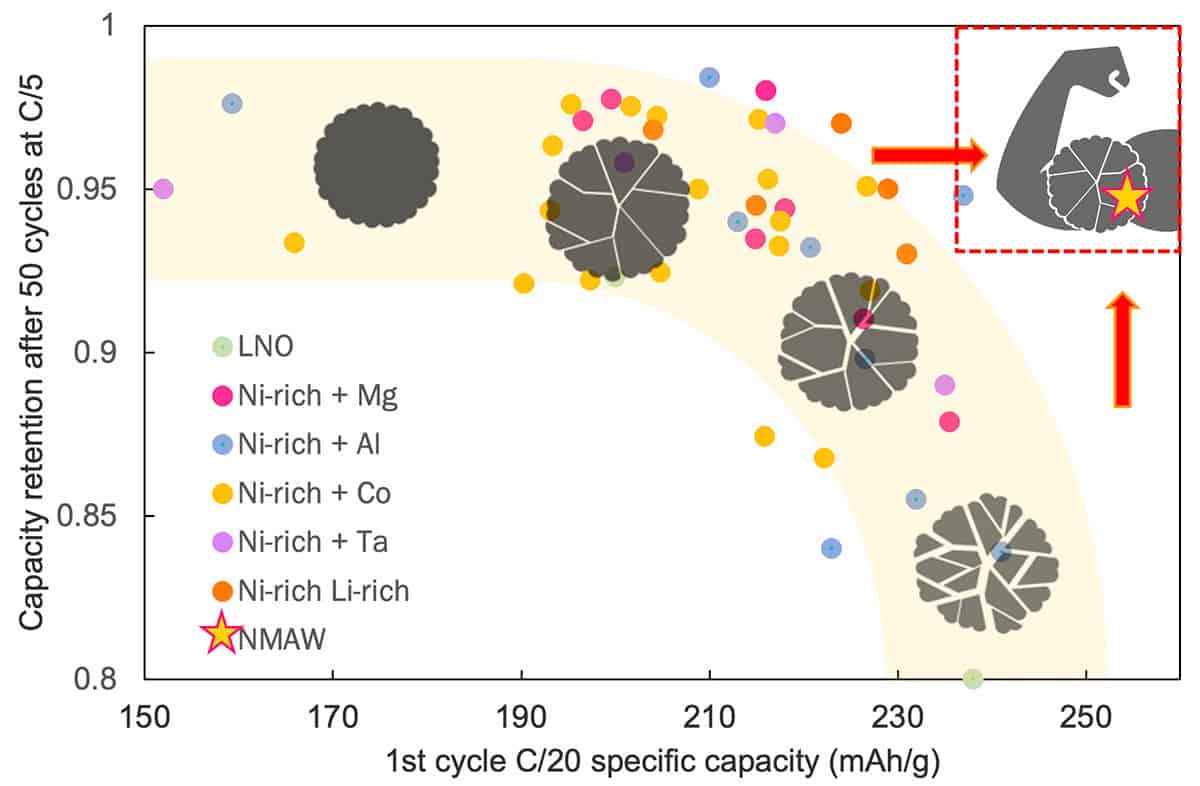

In this work, Al and W are compared as individual dopants as well as co-dopants to arrive to an optimal cathode active material design. The objective is to improve the energy density of the materials without compromising cycle life; a feat which was previously thought unattainable for Ni-rich, Co-free layered oxide materials.

The findings emphasize the importance of understanding the effect of chemical composition and synthesis conditions on the morphology of the material particles. In turn, this morphology plays a determinant role in the cycling performance of the electrode.

In addition to conventional material characterization methods (such as x-ray diffraction, scanning electron microscopy, incremental capacity analysis, etc.), measurements of the particles’ strength were also analyzed to provide better insight on how the material will perform in an expanding-contracting electrode. Mechanical resilience if often overlook when studying and designing cathode materials, however, particularly in materials that are prone to microcracking, this information provides an important piece of the puzzle to understand the degradation mechanisms of the electrode.

This led to the development of a Co-free cathode material which can provide a capacity of 260 mAh/g on the first cycle while retaining 95% capacity after 50 cycles in half cells cycled to 4.3 V. At a lower upper-cutoff voltage of 4.06 V, this material delivers 220 mAh/g with no observable capacity loss after 100 cycles.

Ines Hamam has obtained her PhD in materials engineering (in 2024) and her MSc in physics (in 2020) from the University of Dalhousie under the supervision of world-renowned battery expert Dr Jeff Dahn. She is now a technologist at BMW furthering the world effort of transport electrification.

The post Pushing the energy-lifetime frontier of Li-ion batteries: optimizing Ni-rich, Co-free cathode materials to maximize energy density and cycle life appeared first on Physics World.